Ensure all connections are secure and use marine-grade wiring. Follow ABYC standards to guarantee safety and reliability.

Boating enthusiasts must prioritize proper wiring to ensure safety and functionality on their vessels. Incorrect wiring can lead to serious issues, including fire hazards and equipment failure. Understanding and following the basic rules for wiring a boat helps prevent such problems.

Using marine-grade wiring ensures durability against harsh marine environments. Properly securing all connections prevents electrical shorts and malfunctions. Adhering to the American Boat and Yacht Council (ABYC) standards is crucial for reliable and safe electrical systems. These guidelines help create a dependable and efficient electrical setup. Always double-check connections and follow established procedures to avoid potential dangers and ensure a smooth boating experience.

Plan Your Wiring Layout

Before starting any wiring project on your boat, it’s crucial to plan your wiring layout. Proper planning ensures safety and efficiency. It helps avoid confusion and potential hazards. Planning also saves time and money.

Sketch A Diagram

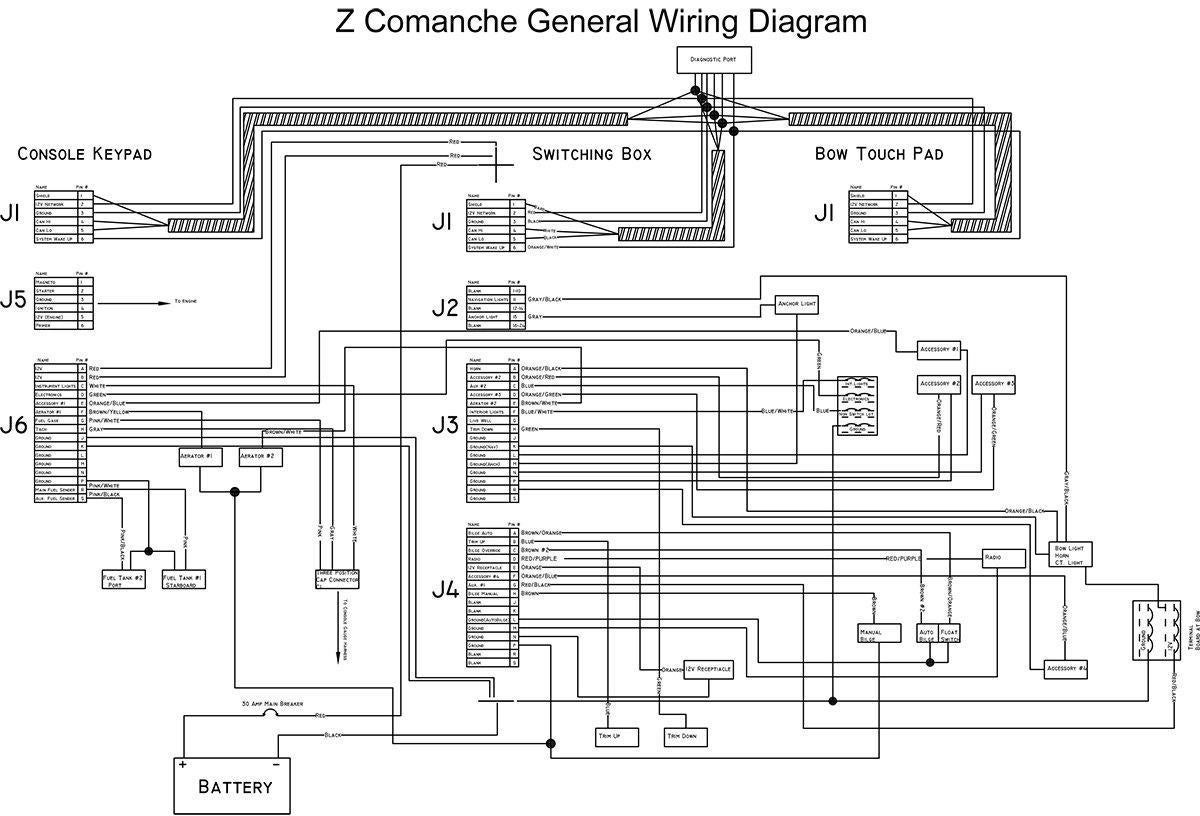

First, sketch a wiring diagram. This provides a visual guide for your wiring project. Use simple lines and symbols. Mark where each component will be placed. Add labels to each line and component.

- Start with the battery location.

- Draw lines to each component.

- Mark switch panels and fuse blocks.

- Include lights, pumps, and electronics.

A clear diagram helps avoid mistakes. It ensures all components are correctly connected. This improves overall safety and functionality.

Label All Components

Next, label all components clearly. Use durable labels that can withstand marine conditions. Label both ends of each wire. This makes maintenance easier.

- Label the battery and its terminals.

- Mark the switch panels.

- Label each fuse and breaker.

- Identify all lights and pumps.

Clear labels prevent confusion. They make troubleshooting quicker and easier. This is especially important in emergencies. Proper labeling helps ensure safe and efficient operation of your boat.

Choose The Right Wire

Choosing the right wire for your boat is crucial. Proper wiring ensures safety and efficiency. It also prevents costly repairs. Here are some key points to consider.

Gauge Selection

Wire gauge is the thickness of the wire. The right gauge depends on the current and length of the wire run. Use a wire gauge chart to choose the correct size.

| Current (Amps) | Wire Length (Feet) | Recommended Gauge |

|---|---|---|

| 0-15 | 0-10 | 16 AWG |

| 15-20 | 0-10 | 14 AWG |

| 20-30 | 0-10 | 12 AWG |

| 30-40 | 0-10 | 10 AWG |

Always opt for a thicker wire if unsure. Thinner wires can overheat and cause fires.

Marine-grade Wire

Marine-grade wire is designed for harsh marine environments. It resists corrosion and is more durable than regular wire.

- Tinned Copper: Marine wire uses tinned copper. It resists corrosion better.

- Insulation: Marine wire has thicker insulation. It protects against water and chemicals.

- Flexibility: Marine wire is more flexible. It is easier to route through tight spaces.

Always choose marine-grade wire for your boat. It ensures longevity and safety.

Use Proper Connectors

When wiring a boat, using proper connectors is crucial. It ensures safety and durability. Boat environments are harsh. You must use connectors that resist corrosion and moisture. Proper connectors also prevent electrical failures and hazards.

Crimping Techniques

Crimping is key to secure connections. Follow these steps for effective crimping:

- Strip the wire insulation carefully. Expose enough wire for a strong crimp.

- Choose the right connector size for your wire. This prevents loose connections.

- Insert the wire into the connector fully.

- Use a proper crimping tool. A good tool ensures a tight and secure crimp.

- Check the connection. Tug lightly on the wire to ensure it is secure.

Proper crimping keeps your connections strong and reliable. This prevents potential electrical issues.

Heat Shrink Tubing

Heat shrink tubing protects your connections. It seals and insulates the connection from moisture.

Follow these steps to use heat shrink tubing:

- Choose the right size tubing for your connector and wire.

- Slide the tubing over the wire before making the connection.

- Crimp the connector onto the wire.

- Slide the tubing over the crimped connection.

- Apply heat to the tubing. Use a heat gun or lighter. The tubing will shrink and seal the connection.

Heat shrink tubing ensures long-lasting, protected connections. It prevents corrosion and wear.

Install Circuit Protection

When wiring your boat, ensuring proper circuit protection is crucial. Circuit protection helps prevent damage to electrical components. It also protects against potential fire hazards. Here’s what you need to know about installing circuit protection.

Fuses And Breakers

Fuses and breakers are essential components in your boat’s electrical system. They protect against overcurrent and short circuits. Fuses are one-time-use devices that need replacing when blown. Breakers can be reset after tripping.

Choosing the right fuse or breaker is critical. Use a fuse or breaker rated slightly above the maximum current expected. This ensures protection without frequent trips or blown fuses.

Location And Accessibility

Place fuses and breakers in accessible locations. This allows for easy inspection and replacement. Avoid placing them in hard-to-reach areas.

Organize fuses and breakers in a centralized panel. Label each fuse or breaker clearly. This helps in quick identification during maintenance.

Ensure the panel is protected from moisture and corrosion. A waterproof box is ideal for marine environments.

By following these steps, you enhance the safety and reliability of your boat’s electrical system.

Grounding And Bonding

Grounding and bonding are crucial for boat wiring safety. Proper grounding prevents electrical shock. Bonding ensures different metal parts avoid corrosion.

Common Grounding Points

Grounding points are vital for safety. Use common points to reduce electrical faults. Here are some common grounding points:

- Engine block: This point connects the engine to the ground.

- Battery negative terminal: Connect all ground wires here.

- Grounding bus bar: Use a bus bar for multiple ground connections.

Bonding Different Metals

Bonding different metals prevents corrosion. Connect different metals with bonding wires. Use marine-grade wires for this purpose.

| Metal | Bonding Wire |

|---|---|

| Aluminum | Use a copper wire with a coating. |

| Stainless Steel | Use a tinned copper wire. |

| Brass | Use a tinned copper wire. |

Ensure all metals are bonded to the same ground point. This prevents potential differences and corrosion.

Credit: www.boatoutfitters.com

Secure All Wiring

Ensuring your boat’s wiring is secure is essential for safety. Loose wires can cause damage. They can also lead to dangerous situations. Here are some tips to help you secure all wiring effectively.

Cable Ties And Clamps

Use cable ties and clamps to hold wires in place. These tools keep wires from moving around. They prevent wires from getting tangled. Choose high-quality ties and clamps. They should be resistant to salt and water.

- Secure wires every 12 inches.

- Use UV-resistant cable ties.

- Check the ties and clamps regularly.

Preventing Chafing

Chafing can damage wires. It occurs when wires rub against surfaces. Use protective coverings to prevent this. Split loom tubing is an excellent choice. It is flexible and easy to install.

| Protective Material | Benefits |

|---|---|

| Split Loom Tubing | Flexible, easy to install |

| Heat Shrink Tubing | Durable, offers tight fit |

Also, ensure wires do not touch sharp edges. Use grommets for holes and pass-throughs. They provide a cushion for the wires.

Avoid Moisture Exposure

Boating enthusiasts understand the importance of keeping electrical systems dry. Avoiding moisture exposure is critical for the longevity and safety of your boat’s wiring. Moisture can lead to corrosion and electrical failures. Let’s explore essential practices to keep your boat’s wiring dry.

Waterproof Connections

Waterproof connections are vital to protect your boat’s electrical system. Using heat shrink tubing and marine-grade connectors ensures a tight seal. This seal prevents water from entering the connection points.

- Heat shrink tubing: Creates a waterproof seal around connections.

- Marine-grade connectors: Resist corrosion and are durable.

Applying dielectric grease on connections further prevents moisture intrusion. This grease acts as an insulator and keeps water out.

Drip Loops

Drip loops are simple yet effective in preventing water damage. These loops allow water to drip off wires before reaching connection points.

- Ensure wires hang lower than the connection point.

- Use cable ties to secure drip loops in place.

Drip loops are especially useful in areas prone to water exposure. They are a low-cost solution to protect your wiring.

Test Your Installation

Testing your boat’s wiring installation ensures safety and functionality. Proper tests help identify faults and ensure the system runs smoothly. Performing thorough tests can prevent future issues and costly repairs.

Continuity Checks

Continuity checks verify that electrical paths are complete. Use a multimeter for this task. Follow these steps:

- Turn off all power sources.

- Set the multimeter to continuity mode.

- Touch the probes to both ends of the wire.

- If the multimeter beeps, the circuit is complete.

Ensure each wire in your system passes this check. This step confirms no breaks or faulty connections.

Voltage Drop Testing

Voltage drop testing identifies resistance within the circuit. Excessive resistance can cause problems. Follow these steps:

- Turn on the power source.

- Set the multimeter to DC voltage mode.

- Measure voltage at the power source.

- Measure voltage at the load (e.g., light, motor).

- Subtract the load voltage from the source voltage.

If the voltage drop is more than 10%, there is a problem. Check for loose connections or undersized wires.

Note: Both tests are essential for a reliable and safe wiring system. Regular checks ensure your boat’s electrical system remains in top condition.

Follow Marine Codes

Ensuring your boat’s wiring is safe and effective means adhering to marine codes. These codes are designed to protect you, your passengers, and your investment. Following marine codes helps prevent electrical failures and ensures your boat meets legal standards.

Abyc Standards

The American Boat and Yacht Council (ABYC) sets standards for boat wiring. These standards help you avoid common wiring issues. ABYC guidelines cover everything from wire size to installation methods.

- Use tinned copper wire for all electrical connections.

- Secure wires every 18 inches to prevent movement and wear.

- Label all wires clearly for easy identification.

Following ABYC standards ensures your boat’s electrical system is safe and reliable. These standards are widely respected in the marine industry.

Coast Guard Regulations

The U.S. Coast Guard also sets important regulations for boat wiring. These rules are mandatory for all boat owners. Coast Guard regulations focus on safety and environmental protection.

- Ensure all electrical systems are properly grounded.

- Install circuit breakers or fuses for all electrical circuits.

- Use marine-rated components to withstand harsh conditions.

Coast Guard regulations help ensure your boat is safe to operate. Following these rules can prevent accidents and legal issues.

Both ABYC standards and Coast Guard regulations are essential for safe boat wiring. Adhering to these codes ensures your boat is ready for the water.

Credit: www.wired2fish.com

Regular Maintenance

Regular maintenance is crucial for safe and efficient boat wiring. It helps prevent potential issues and extends the life of your electrical system. Follow these basic rules to keep your boat’s wiring in top shape.

Inspect Annually

Inspect your boat’s wiring at least once a year. Look for signs of wear and damage. Check connectors, terminals, and wires for any issues. Replace any damaged parts immediately to ensure safety.

Address Corrosion

Corrosion is a common problem in boat wiring. Saltwater and moisture can cause corrosion on connectors and terminals. Use corrosion-resistant materials for your wiring. Apply anti-corrosion spray to protect your connections.

| Corrosion Prevention Tips |

|---|

| Use marine-grade wiring |

| Apply dielectric grease |

| Seal connections with heat shrink |

Credit: www.safe-skipper.com

Frequently Asked Questions

What Are The Basic Rules For Wiring A Boat?

Ensure proper insulation, use marine-grade wires, secure connections, follow the wiring diagram, and install circuit protection.

Why Use Marine-grade Wires For Boat Wiring?

Marine-grade wires are durable, resist corrosion, and handle harsh marine environments, ensuring safety and reliability.

How To Ensure Proper Insulation In Boat Wiring?

Use heat-shrink tubing and waterproof connectors to protect wires from moisture and prevent electrical shorts.

Why Is Circuit Protection Important In Boat Wiring?

Circuit protection prevents electrical fires and equipment damage by cutting off power during overloads or short circuits.

Conclusion

Mastering boat wiring ensures safety and efficiency on the water. By following these 10 basic rules, you’ll avoid common pitfalls and enjoy smoother sailing. Proper planning, quality materials, and regular maintenance are key. Implement these tips to keep your boat’s electrical system in top shape and enhance your boating experience.